The Importance of Tool and Die Makers in Injection Mold Building

(Updated January 2022)

The tool and die makers are expert workers or precisely put artisans of a manufacturing unit. These machinists learn the trade of injection mold building through a combination of hands on practical training with academic course work during an apprenticeship period. One can train to become a tool maker, a die maker, a tool fitter, or a mold maker depending upon one’s area of concentration in which he/she works. They can specialize in making fixtures, jigs, dies, machine tools, molds, cutting tools, gauges, and many other manufacturing tools.

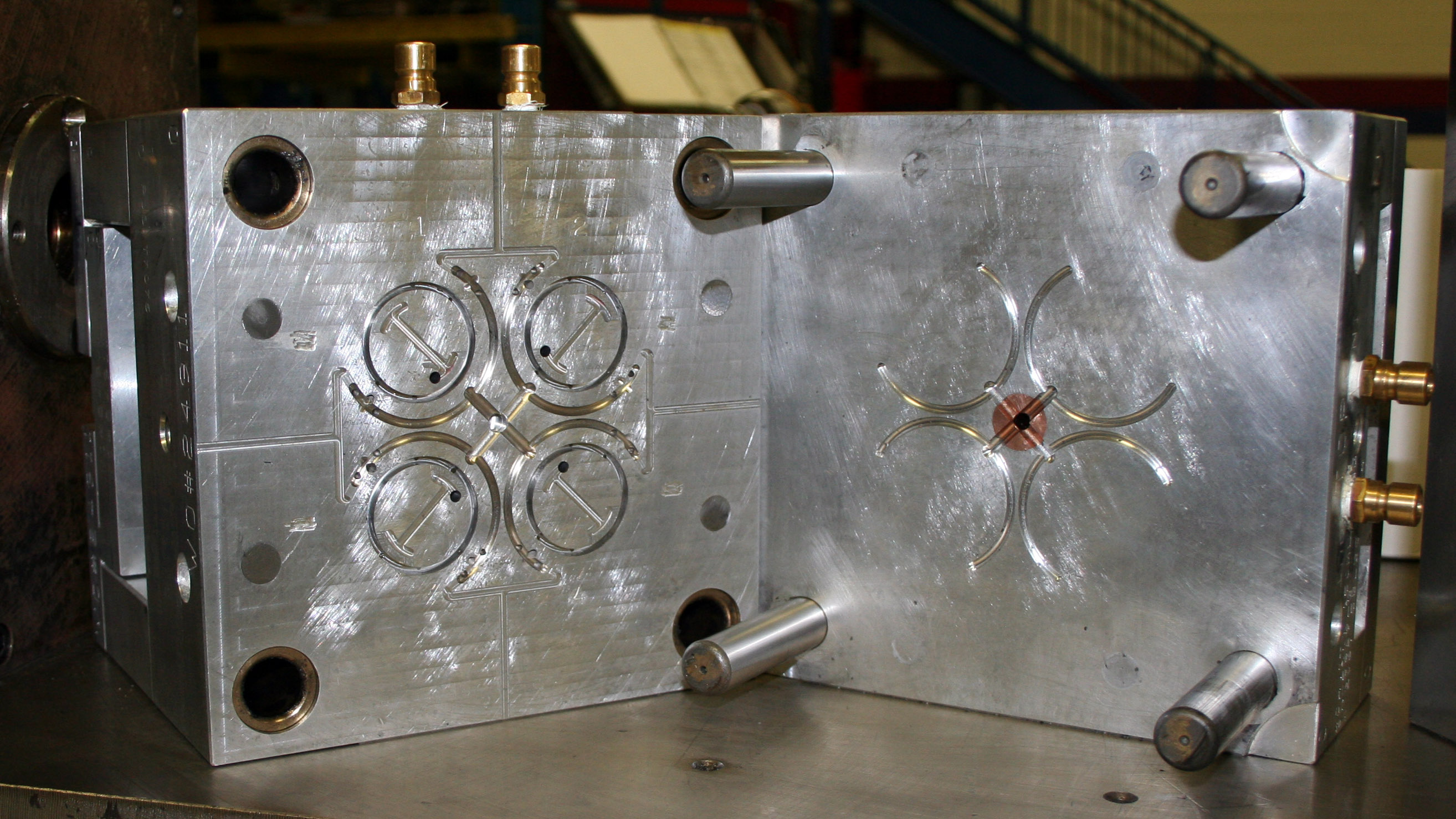

A tool or die maker’s job is highly significant as this industrial job requires one to create molds and parts by researching blueprints. Injection mold building can be a complicated process and the skilled tool and die machinists have advanced training to calculate the feeds/ speeds required to make precise cuts with drills, end mills, and other sophisticated CNC cutting tools. These industrial personnel have to work in close consultation with design engineers in producing the product.

As learning the art of injection mold building needs basic training, many tool and die, makers, begin this foundation course with an apprenticeship program under an employer. Having some prior qualifications like knowledge in science, mathematics, and engineering/design technology can be an added advantage. To achieve the Journeyman tool and die maker’s status in a reputed injection mold building industry, one has to undergo a 4 to 5 year apprenticeship program. Such an exhaustive period of on-the-job training leads to mastery of the field of tool and mold making. No doubt that these versatile people are an asset to any manufacturing industry.

Basically, the tool and die maker apprenticeship program deals with the training needed to make and forge dies. The curriculum offers professional training in metal processing, forging, grinding, and manufacturing methods used in the injection mold building industries. The training initially includes a fundamental review of the technical skills needed in drawing, safety, and measurements and then goes on to train the students in metallurgy, tool grinding, and manufacturing process. The comprehensive training program should meet the BAT standards namely the Bureau of Apprenticeship cum Training principles enabling one to reach the top position career in an injection mold building industry.

Crescent Industries understands quality molds make quality injection molded products which is why our tooling facility is staffed with journey-skill level mold makers utilizing CNC equipment and advanced technologies to manufacture injection molds. Check out Crescent's injection mold building capabilities.

Topics:

Related Articles

-

Apr 10, 2025

How Are Injection Molds Made for Plastic Manufacturing?

Read MoreDo you have a part design and need an injection mold built? Are you interested in finding a tooling...

-

Sep 06, 2023

What is Plastic Injection Mold Tooling?

Read MoreInjection mold design gives you the ability to create parts with ease. You fill a mold designed to...

-

Nov 16, 2022

Project Management for Injection Molding Means Product Success

Read MoreThere’s a difference between project management and engineering management, and in the field of...