Plastic Injection Molding Process Monitoring for Quality Components

For engineers, injection molding process monitoring plays a significant role in the quality and efficiency of molding processes. An injection molding partner that engages in injection molding process monitoring is focused on maximizing productivity while maintaining quality, delivering the best results for your investment.

In this piece, we will look at what injection molding process monitoring is, how injection molders implement and manage it, and how you — as an engineer — gain benefits from it.

Overview of Process Monitoring

In a big-picture sense, injection molding process monitoring is a way of overseeing the results of key molding process parameters, including:

- Injection pressure

- Melt temperature

- Mold temperature

- Air temperature

- Filling time

- Packing/holding time

- Cooling time

- For a deeper dive into these process parameters, go to Injection Molding: Fill, Pack, & Hold Process.

What Is Real-Time Injection Molding Process Monitoring?

With a high-level understanding of injection molding process control, we can now take a closer look at how this practice is implemented and how it works:

- Hardware: The first step in implementing injection molding process control is adding the right hardware to equipment. This is typically in the form of sensors that measure and communicate factors such as temperature (for the mold, material and air), injection pressure and timing for each step in the molding process.

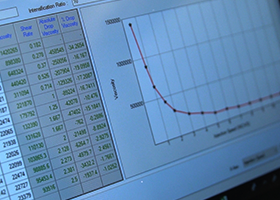

- Software: Once readings and data are collected via process monitoring, they are used in several ways — all facilitated by software. Software enables real-time analysis of data readings, comparison against historical data and optimal parameters.

- Real-time communication and monitoring: Today’s monitoring equipment is effective primarily because of the real-time action that it enables. Wired or wireless communication enables near-instantaneous transmission and analysis of real-time data. This allows the injection molder to evaluate efficiency of the injection molding process parameters and make real-time production decisions to increase quality and reduce rejects.

- People: Without the right people on hand, none of the above investments will be as effective as they can be. Trained and experienced personnel make sense of data analytics, monitor processes, and ultimately direct any necessary action based on these readouts. These actions are at the core of the benefits of process monitoring, which we will expound upon next.

Benefits of Injection Molding Process Monitoring

Process monitoring can yield the following benefits:

- Identify process inefficiencies: As briefly mentioned above, molding process monitoring enables data collection, analysis, comparison and, ultimately, action. In this process, deviations from programmed-in optimal parameter ranges, as well as from historical data, can quickly be identified and analyzed to determine whether adjustments are necessary. Fluctuations in parameter readings can mean that aberrations are present in the process — whether in process times and temperatures, or in equipment calibration. When operating outside of optimal parameter ranges, injection molding will usually not be as efficient as it can be. This could lead to part rejects, along with longer production times and increased costs over the long run. Process monitoring can quickly identify and rectify these inefficiencies.

- Monitor mold performance: A mold typically has a rated service life, as well as a recommended maintenance interval. With process monitoring, your molding partner gain more insight into the actual performance and health of the tool, allowing them to make informed decisions about maintenance and mold repair. For example, monitoring data may show that the mold is still operating within acceptable ranges at a scheduled maintenance interval.

Conversely, data can identify potential issues that occur between scheduled maintenance — potentially preventing damage to the mold and equipment. In addition, monitoring data can give you a much more accurate picture of when it’s time to replace a mold. - Proactive quality assurance: Quality assurance is typically a reactive, hands-on process: inspecting finished pieces and rejecting those that are not to spec. Injection molding monitoring allows for a more proactive quality assurance process, identifying potential defects right when they occur, and allowing monitoring personnel to earmark rejected parts in advance.

In addition, monitoring can improve quality assurance and reduce defects through the real-time monitoring, analysis and adjustment benefits described above. By identifying potential quality root causes from the onset, technicians can make adjustments to help ensure that equipment continues operating and producing parts to spec — resulting in faster overall production speed and time-to-market.

Now that you understand the concept of plastic injection molding process monitoring, check out this article "The Role of Injection Molding Experts in Injection Molding".

You should also look for a partner that will fit your post-processing operations to consolidate vendors and understand plastic injection molding costs by evaluating total cost of ownership. To get all these resources, go to the Complete Guide to Plastic Injection Molding now.

Resources:

http://www.injectionmoldingplastic.com/injection-molding-process-monitoring-parameters.html https://revpart.com/injection-molding-process-control/

Topics:

Related Articles

-

Mar 19, 2025

Top 6 Advantages of Injection Molding for Your Project

Read MoreInjection molding — the process of injecting molten resin into a mold — is one of the most...

-

Feb 19, 2025

Injection Molding vs CNC Machining: Which Method to Choose?

Read MoreEvery year, humans produce and use countless plastic products in various shapes, sizes, and...

-

Oct 03, 2024

Injection Molding Uses: Exploring Applications Across Industries

Read MoreInjection molding is one of the most versatile manufacturing processes, with a wide range of...