How Long Does an Injection Mold Last? | Durability Factors

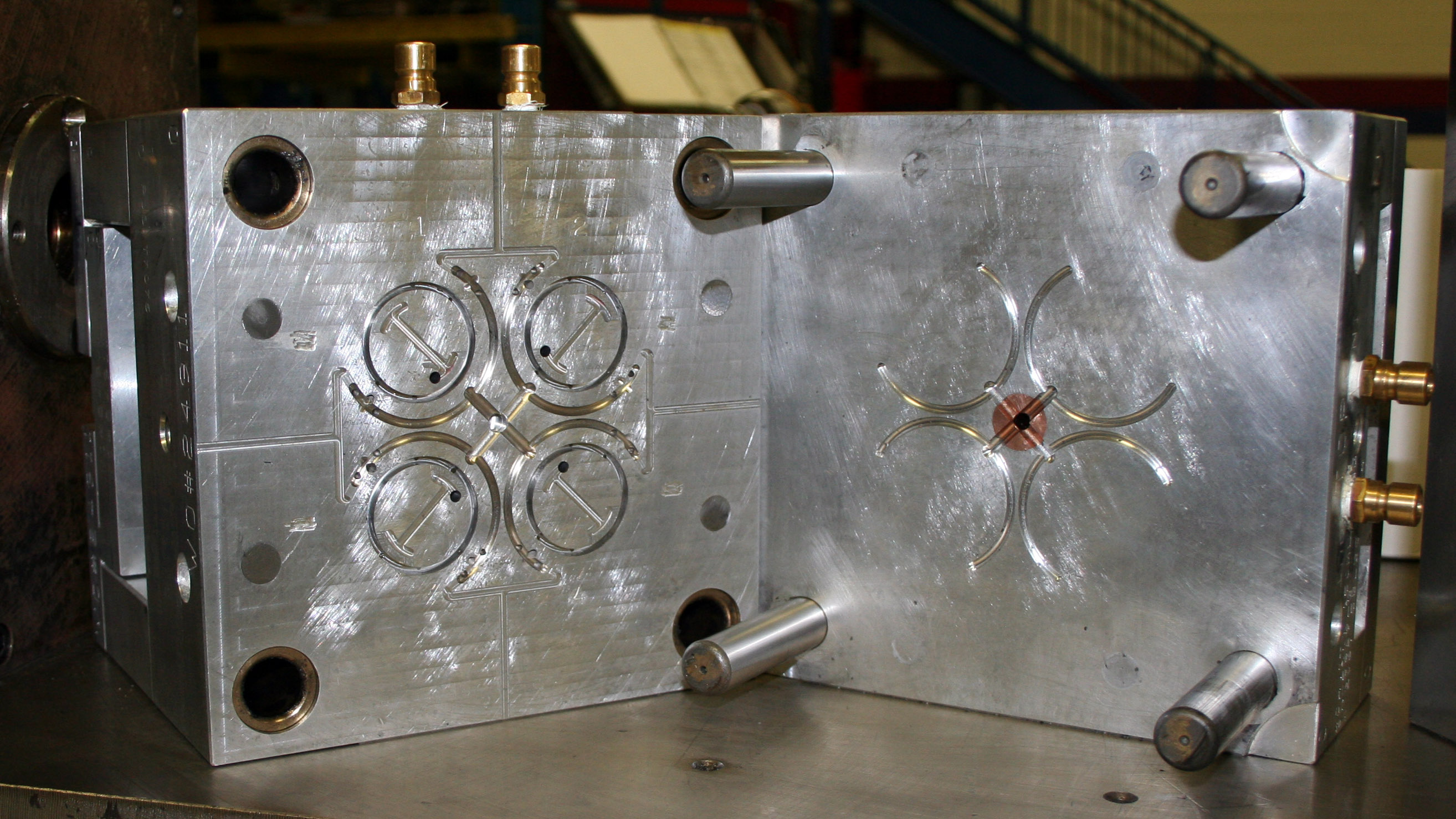

Plastic injection molds can manufacture custom parts in numerous industries with great accuracy and reliability. The process is also considerably faster and cheaper than alternative methods. However, all those benefits are contingent on the durability and longevity of the injection mold tooling.

So, how long does an injection mold last? The life span of an injection mold is measured through use cycles rather than any particular time unit. It's something you must know when working with plastic injection molding tools. However, the answer depends on a host of factors you can control early in the manufacturing process to ensure better and longer-lasting molds.

What Is the Average LifeSpan of an Injection Mold?

The average life span of a mold is defined by how many times it can be used to manufacture plastic parts before it begins to deteriorate and affect the quality of the final product. Most plastic injection molds are made for high-volume production, lasting between 500,000 and 1,000,000 use cycles. Regular maintenance and following manufacturer guidelines give you the best chance of hitting the upper limit of the estimated life span.

Low-volume production or prototype molds tend to have a significantly shorter life span, ranging between 1000 and 5000 cycles. They’re cheaper to manufacture and often made from less durable materials. They prioritize cost over longevity, making them less than ideal for long-term and high-volume projects.

Note that molds can also drop in quality due to faulty storage conditions, even when not in use. Exposure to direct sunlight or unrecommended temperatures for extended periods can significantly cut their life span.

Factors Influencing Mold Durability

Several key factors influence whether or not you’ll be able to make the most of an injection mold. These include material selection, mold design, the operating environment, and maintenance.

Understanding and prioritizing these factors early in the manufacturing process can elongate the service life of your injection mold and retain the quality of the injection molded parts.

Material Selection

The selection of the mold materials goes beyond a material’s ability to capture fine details and textures. High-quality mold materials can significantly prolong the life expectancy of your mold.

One example is hardened tool steels vs. soft steel molds, either hardened or pre-hardened steel. While harder steels are more expensive, they’re incredibly durable and can deliver higher-quality, more reliable results for longer.

Mold Design

The design of the injection mold tooling can also significantly affect its life span. Complex part designs that are very detailed, like thin walls and fine features, can be easily damaged, so having an expert in mold design, building, and molding can help mitigate these risks.

Other design factors to consider include surface finish, the placement of ejector pins, and the flow lines.

Operating Environment and Maintenance

The environments in which the mold is used and stored can also noticeably affect an injection mold's life span. In storage, elements such as high humidity, high temperature, and corrosive materials can be particularly detrimental to metallic molds.

Regular maintenance of the mold can prolong its life. This includes cleaning the mold regularly, lubricating moving and high-friction parts, and inspecting the mold for early signs of wear or damage.

Ensure Mold Durability with Crescent Industries

The life span of an injection mold is a vital consideration before investing in any injection mold. Understanding the factors that influence a mold’s durability is important so you can take steps to ensure your manufacturing partner reaches the full potential of your mold. We know this can be overwhelming. Luckily, Crescent Industries can help!

Crescent Industries is an employee-owned, USA-based leading provider of plastic injection molding services. They use their advanced engineering capabilities to design the right injection mold for your next manufacturing project. Their specialties lie in medical, pharmaceutical, dental, defense, and industrial manufacturing. They have over 75 years of experience in plastic injection mold tooling and molding.

So whether you’re looking for the most durable mold material or one that captures the finest details for a smooth finish, the expert engineers at Crescent Industries can help you start your next project with confidence. Contact Crescent today.

Topics:

Related Articles

-

Apr 23, 2025

How Long Does an Injection Mold Last? | Durability Factors

Read MorePlastic injection molds can manufacture custom parts in numerous industries with great accuracy and...

-

Apr 10, 2025

How Are Injection Molds Made for Plastic Manufacturing?

Read MoreDo you have a part design and need an injection mold built? Are you interested in finding a tooling...

-

Sep 06, 2023

What is Plastic Injection Mold Tooling?

Read MoreInjection mold design gives you the ability to create parts with ease. You fill a mold designed to...