Over 75 Years of Injection Molding & Tooling Expertise

Crescent Industries has been a marketplace leader in delivering custom injection molding, tooling, and other post-molding services, all based on design for manufacturing principles.

What Brings You to Crescent?

Our Customized Solutions

How We Work

REQUEST A QUOTE

Start a quote

The Markets We Serve

We've been shaping these market segments for 75+ years. Our quality management system and certifications are dedicated to those markets, including ISO 13485 certification and ITAR registration.

-

Medical & Pharmaceutical

Explore Our Medical Molding ExpertiseWe specialize in manufacturing Class I, II, and III components and devices, utilizing a wide variety of medical grade resin materials.

-

Military & Defense

Recognized as an ITAR-Registered Manufacturer by the U.S. State Department, we have decades of experience in the defense industry. Currently, our CMMC SRRS score is 84, working towards 110 CMMC 2.0 with regard to preventing, detecting, and responding to cyber threats.Discover Our Military-Grade Solutions -

Industrial & OEM

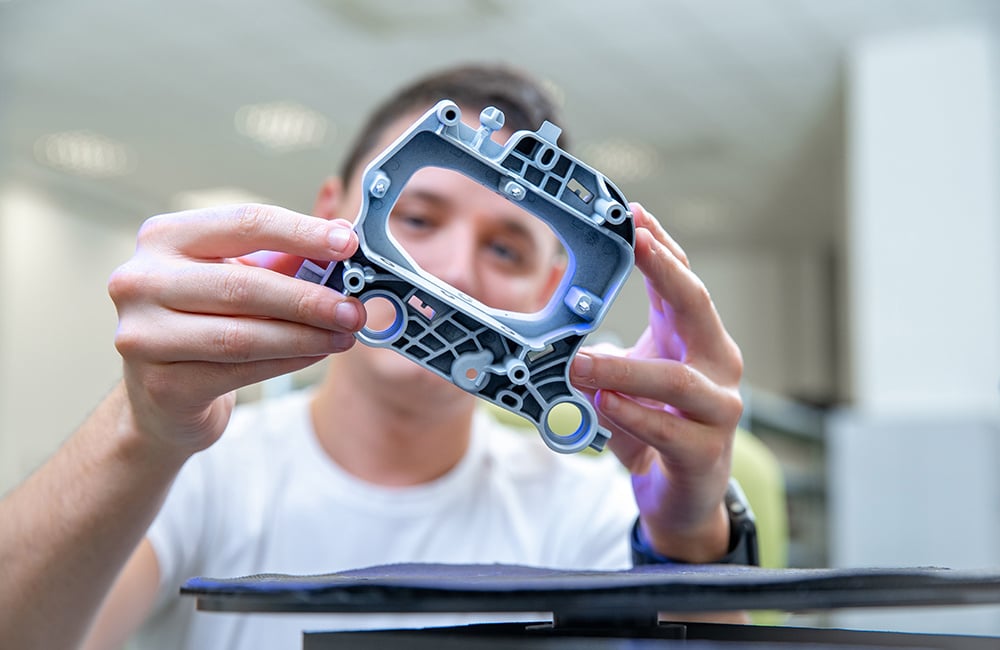

With a tonnage capacity of 11 tons to 450 tons, as well as an unmatched level of vertical injection molding expertise, we develop custom product solutions for a wide range of diverse industries.Precision Molding for Complex Parts

Resources

CRESCENT CASE STUDIES

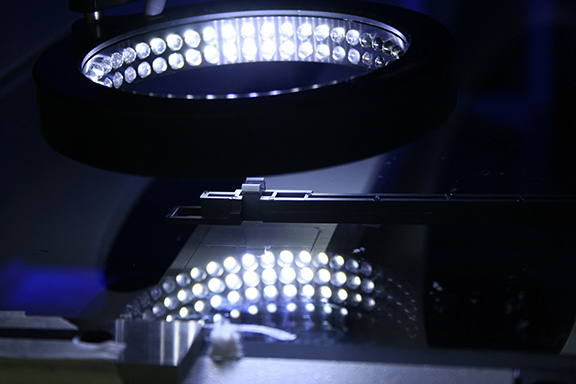

Full Service Cleanroom Injection Molding Solution

The Challange

The Solution

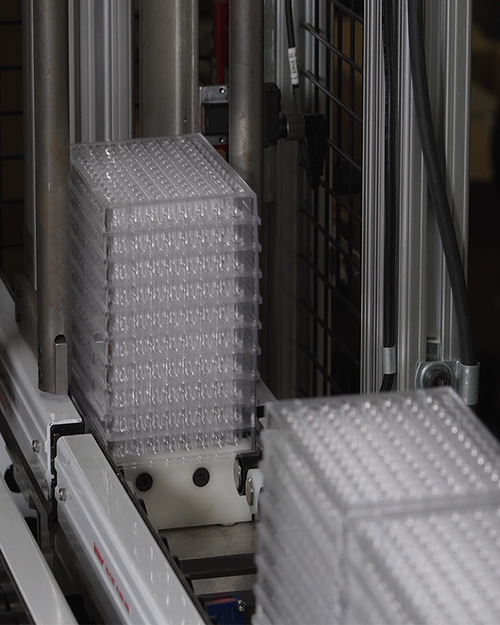

Custom Automated Solution

The Challange

The Solution

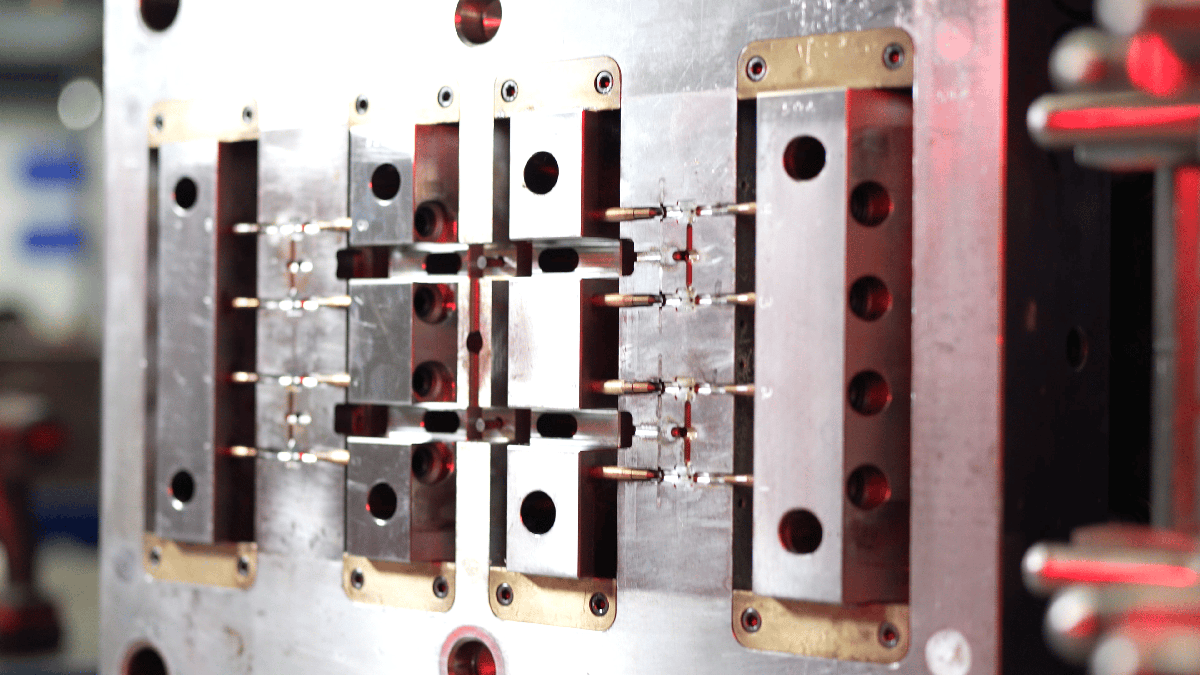

We Started By Designing And Building End-Of-Arm-Tools (EOAT) For Each Of The Four Molds. We Use A Quick Change Feature For Each EOAT, Allowing Easy And Accurate Switching Back And Forth During Mold Changes.

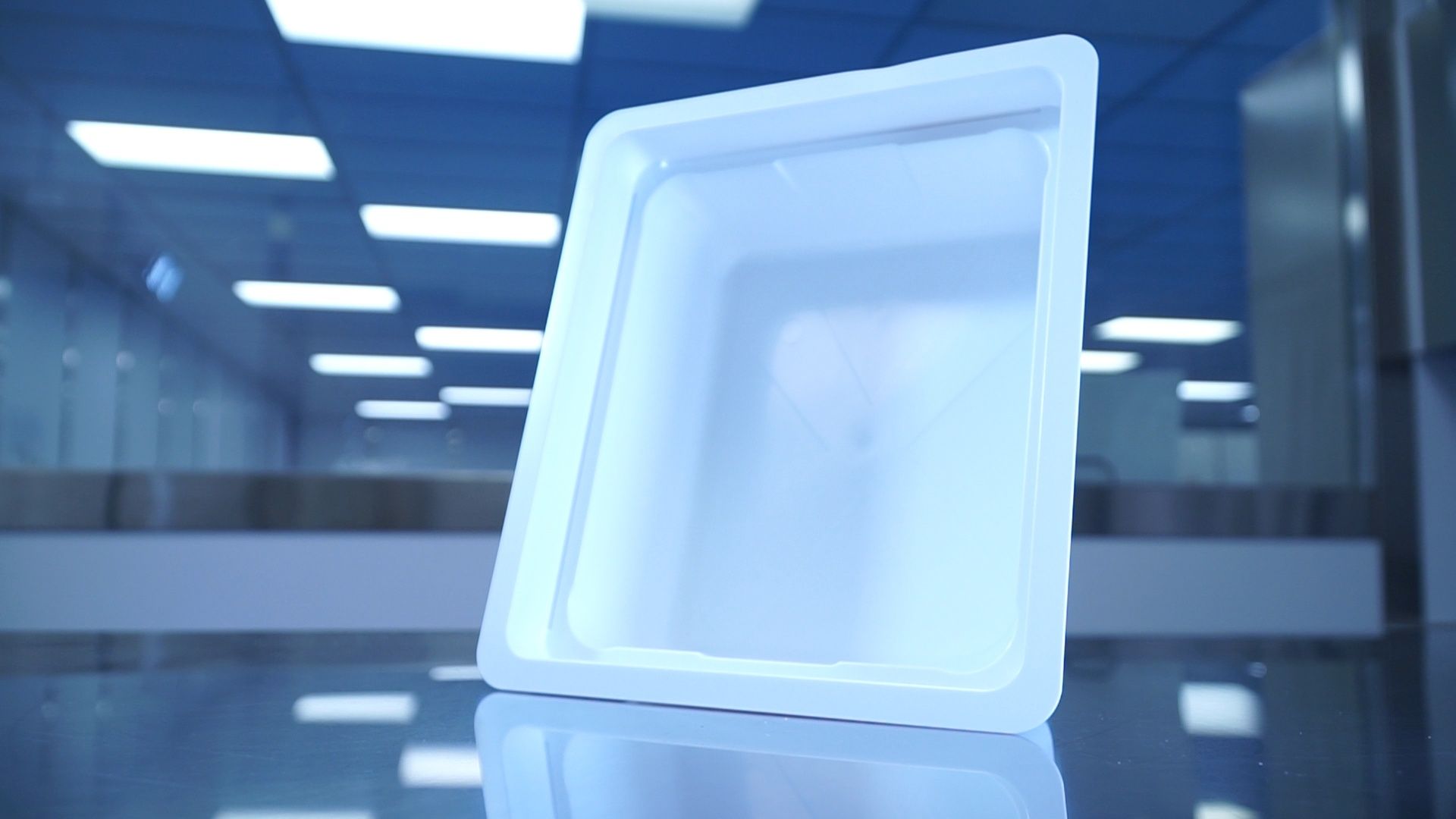

DFM Results Change Manufacturing Outcome

The Challange

The Solution

Blogs

-

Jan 14, 2026

Shortlisting U.S. Injection Molding Partners for Regulated Industries

Read MoreThe U.S. injection molding industry accounted for $42.85 billion in revenue in 2022 and is expected...

-

Oct 28, 2025

Injection Molding Compliance: Quality Validations Explained

Read MoreUnderstanding Quality Validations in Injection Molding

Precision and repeatability are the...

-

Oct 08, 2025

Medical Device Cleanroom Manufacturing: Plastic Injection Molding

Read MoreWhy Cleanroom Manufacturing Matters for Medical Devices

Medical devices are subject to strict...

About crescent Industries

Contact us today to learn more about our services, and how we can play a part in helping you achieve success.