quality standards at crescent

High-Quality Injection Molding Raising Industry Standards

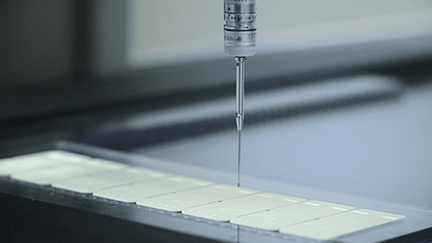

Crescent Industries is devoted to providing quality and excellence in our plastic injection molding services. Our quality team is made up of engineers and technicians who ensure all parts meet compliance standards and customer specifications. Our sophisticated quality lab is equipped with a 3D scanner, video measuring and inspection equipment, and optical comparators that deliver accurate, detailed measurements and inspections. We utilize over 488 gauges, which are maintained and kept in good working order through our in-house calibration system. Currently, our CMMC SRRS score is 84, working towards 110.

It is our commitment to provide World-Class Resources and a Quality Management System that maintains a competitive advantage. We pledge our best effort to satisfy our customers’ requirements regarding quality, service, value, and delivery.

OUR QUALITY PRACTICES

Quality Standards

We are 100% invested in maintaining the highest quality standards with our state-of-the-art quality lab.

- First Article, In-Process, and Final Inspections

- DOE's, SPC, Capability Studies, Control Plans, & Master Plan Validation

- Validated QMS Module within our ERP System provides full-lot traceability

- Complete Incoming Material Inspections

- Robust Corrective & Preventative Action Reports

- Risk Mitigation Through Process/Product Failure Mode and Effects Analysis (PFMEA)

- Manage Customer Audits and Internal Audits of our Quality Management System

- Validation Protocols that follow IQ/OQ/PQ and PPAP Requirements

- Coordinate Testings of Material with our Outsourced Partners

ISO 13485 Certified

Our philosophy is to push quality standards through all core internal processes and procedures, so we consistently provide product that conforms to contracted specifications. When your project requires a highly-controlled environment, we are equipped to manufacture and assemble in our Class 7 (10K) or Class 8 (100K) clean rooms.

- ISO 13485:2016 Certified

- Certified ISO 7 Cleanroom Facility

FDA Registered Facility

International Traffic Arms Regulations Registered

- ITAR Registered

- CMMC 2.0

- JCP #0088784

- Cage Code 4A8G2

QUALITY IS CRITICAL

Meeting Military Specifications requirements consists of many things, but it all begins with precision mold design and up-front engineering & development. Our in-house tooling capabilities combined with our engineering expertise gives our partners the ability to work closely with an experienced engineering team to help develop critical components for “mission” critical applications.

Crescent practices Statistical Process Control (SPC) for measuring and controlling quality during the manufacturing process. Our equipment and gauges are used to verify critical dimensions on validation protocols, capability studies, first articles, production runs and final inspections. Our highly-trained quality associates practice routine inspections on all shifts.

4 WAYS CRESCENT ENSURES QUALITY INJECTION MOLDED COMPONENTS & DEVICES

At Crescent, we prioritize quality and adhere to the highest industry standards. With our ISO 13485 certification, FDA, and ITAR registration, we meticulously follow all necessary documentation, validations, and security protocols. Rest assured; we have the expertise and capabilities to excel in these industries.

Discover more in this informative video.