Crescent Doubles Production Capacity While Cutting Production Costs by 18%

Demand for a Diagnostic Tool Outruns Production Limits

A global OEM and longtime Crescent Industries customer needed a customized, automated, and high-throughput solution to capitalize on a successful product—and they needed it fast.

As demand for its regent dipstick exploded due to rapidly increasing market share, this OEM struggles to supply hospital labs with a vital tool used for patient screening. The OEM's current injection mold and labor-intensive downstream process both had to be completely redesigned for much higher throughput.

-

Program Challenges: Meet the Surge in Demand without Surging Production Costs

This customer turned to Crescent to take over production for this part, which was originally being manufactured by another contract manufacturer. As a result of this vendor consolidation, the original 4-cavity hot runner mold was transferred to Crescent. While this tooling served them well in the past, both the OEM and Crescent knew it wouldn’t meet forecasted demand. A new mold would be needed.

The dipstick is a simple, single-use plastic part used for patient screening which is bought in bulk and packaged in sleeves. What wasn’t simple was designing a new 8-cavity mold and a fully automated work cell to produce the dipstick. Crescent had to carefully manage the many competing constraints of this price-sensitive product:

- Upfront equipment costs

- Production throughput

- Shop floor space

- Per part cost

- Injection molding cycle time

On top of that, reserve production capacity had to be designed into the whole workflow to avoid this same problem down the road.

-

Crescent’s Solution: More Mold Cavities & a Custom-Designed Automated Work Cell

The jump in the OEM’s production requirements came in two waves. The first wave was met when Crescent proposed, designed, built, and put into operation a new 8-cavity hot runner injection mold. This replacement for the original 4-cavity hot runner tooling satisfied the new annual demand of 2.5 million parts and had plenty of capacity to spare. The OEM was now well-positioned to handle yet another ramp-up in production.

Insufficient spare capacity caused a bottleneck in the downstream process during the second wave, due to a demand of 4.5 million parts per year. A full-time operator was needed to unload and package the dipsticks from the mold, but this would only maintain product flow for current demand. A more efficient and less labor-intensive solution was needed for further production increases.

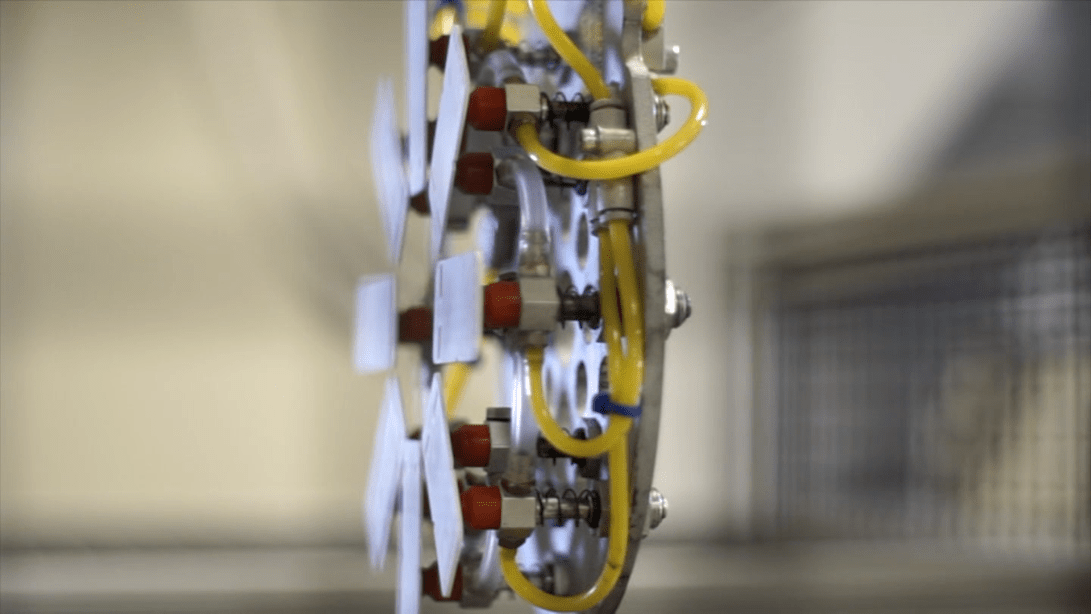

By partnering with an outside team, Crescent’s internal automation specialists and engineers designed a dedicated and fully automated work cell to produce this product. They combined the new 8-cavity hot runner mold with 5-axis robots equipped with custom end-of-arm tooling. The robots remove the molded parts from the press and then place them on an automated turntable, stacking them until there are enough to be placed into a packaging sleeve.

Crescent combined the new tooling with an automated downstream workflow and thus allowed the OEM to capture more savings since Crescent did not need a full-time operator on this line, saving labor costs.

-

Results: Production Capacity for Future Growth, 18% in Production Savings Now

This custom automated work cell now makes 4.5 million parts annually. If need be, this line can more than triple its current production rate. By dropping production costs by 18%, the new mold and automated work cell provided by Crescent have also had a profound impact on the OEM's bottom line. The real impact, however, is being delivered to the innumerable patients who benefit from the fast and accurate test results this reagent dipstick helps produce, leading to increased patient quality of life through quick treatment following diagnosis.

Why Choose Crescent?

Discover the countless benefits of partnering with us for all your injection molding manufacturing needs and let us show you why we are the perfect match for your business.