Crescent Industries Streamlined Mold Design & mold builds for a Complex Orthopedic Device

Our client was a manufacturer that makes medical devices for orthopedic surgeries. This device is used in surgeries to help repair tendons and ligaments.

The challenge

The Solution

The Outcome

DETAILED PROCESS

As our partner, you receive a custom, proactive approach to your project, leveraging scientific data and testing to ensure a smooth, cost-effective manufacturing process.

The step-by-step process Crescent undertook for their client's surgery device and highlights what all clients can expect when working with our manufacturing and engineering teams.

-

Mold Conceptualization & Design

Includes a full disclosure of the mold design and function using experience, judgement, and artistic skill for conceptualization.

Action features, runner, gates and venting, determine mold steels, type of mold, ejection system and design.

Anticipated part volume needed annually will determine the number of cavities, and mold steels, and these then determine the injection mold costs

-

Mold Fill Simulation Performed

Helps to uncover and address any issues upfront with the mold deisgn before cutting the steel, such as the potential for parts to stick, as uncovered in this project.

All of these mold design decisions, mold fill simulation results are reviewed with the customer and the mold design is approved.

-

Dedicated Project Management Team

Crescent's PMO team uses collaborative planning tool software to communicate mold building and project status internally and to the customer.

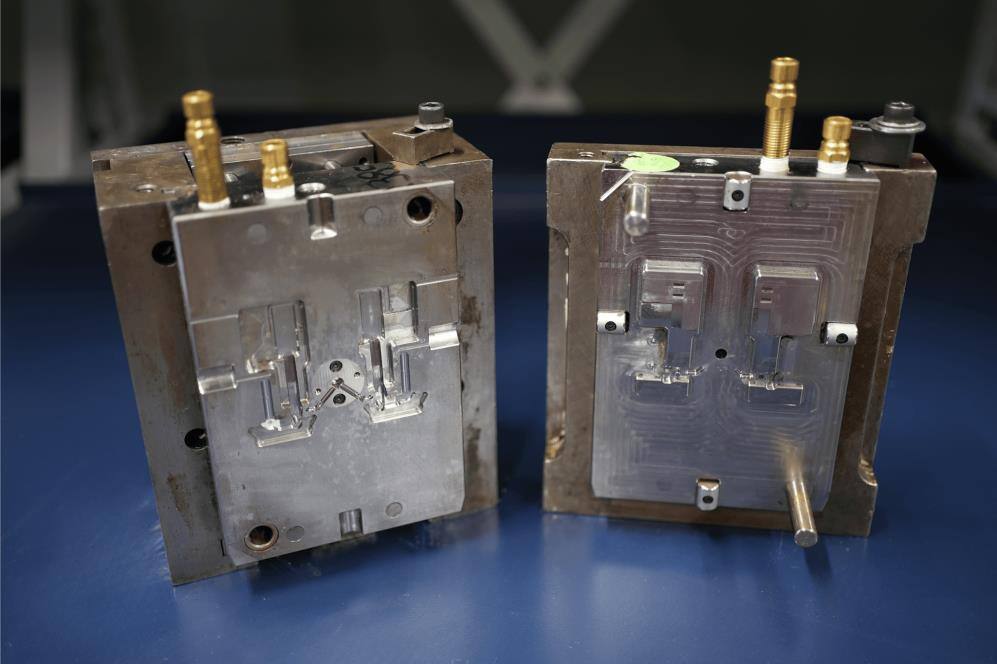

Once the injection mold design is approved, it moves to journeyman tool builders to fabricate the injection molds.

-

Injection Molding Process Developed

Robust process uses scientific data to ensure the injection mold produces quality parts reliably and repeatably and is developed by a dedicated process engineer.

The process engineer will gather drawings of the parts, material data sheets, and mold simulation to get baselines for barrel temperatures, water temperatures, pressure, and cycle time. The cooling time, hold time, pressure are all determined and documented during mold trial and then documented for customer approval.

-

FAIR & Quality Documentation for Approval

Part size, appearance, and mold function are documented and debugged to hit quality specifications of the parts

Crescent's Form 1061, FAIR, and quality documentation of part measurements and sample shots are sent to the customer for approval.

-

Launch to Full Production

Once all steps were complete and the customer fully approved, the injection mold or molds in this case our launched to full production.

Ready to take the next step?

Download our FREE white paper to learn:

• Key considerations like material selection, tool construction, and more

• The most effective approach to cycle time and production efficiency

• Cost considerations to get the biggest impact for your dollar

• How to select the right injection mold tooling partner

• Tips to make the biggest impact and set yourself up for manufacturing success

Download the white paper today.

Why Choose Crescent?

Discover the countless benefits of partnering with us for all your injection molding manufacturing needs and let us show you why we are the perfect match for your business.