What Exactly Does a Medical Device Contract Manufacturer Do?

The advancement of new technologies has led to an explosion of growth in medical technologies. The United States alone accounts for nearly half the medical device sales, with the expected market size reaching 964 billion by 2030.

As the demand for medical devices grows, so does the need for medical device manufacturing. In the fast-paced world of health care, medical device contract manufacturing has a vital role to play.

What Is a Medical Device Contract Manufacturer?

Medical device contract manufacturing is the outsourced manufacturing of medical devices for the healthcare marketplace. In simple terms, their role is to produce high-quality, reliable medical equipment on behalf of other companies.

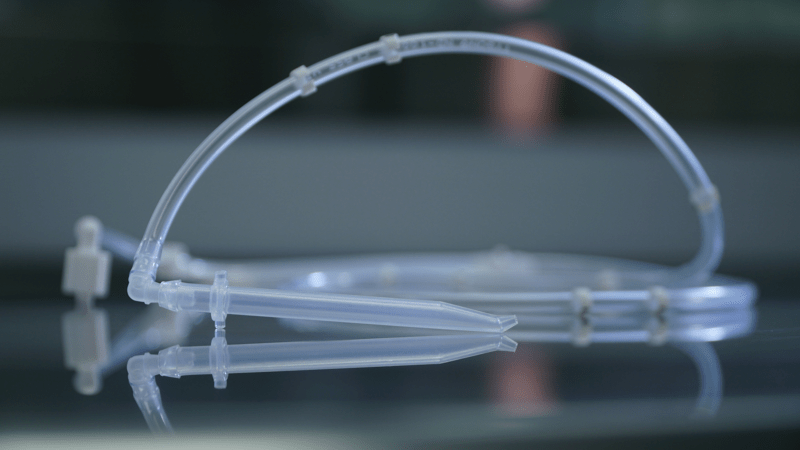

They work with medical device companies to make components or complete assemblies of products for Class I, II, and III medical devices. In addition to production, they may provide other services, like regulatory compliance, packaging and labeling, and sterilization.

Working with medical device contract manufacturers allows original equipment manufacturers (OEMs) to benefit from a streamlined supply chain to deliver high-quality products that meet all industry guidelines. In addition, with the help of contract manufacturers, they can meet delivery deadlines, reduce production costs, and focus on innovating their devices.

What Does a Medical Device Contract Manufacturer Do?

Medical device contract manufacturers' production and support services help OEMs bring their medical devices to the market. But what exactly do contract manufacturers do?

Here are some of the most important responsibilities of a medical device contract manufacturer.

Meet Regulations and Requirements

Medical devices are essential to safeguarding public health — used to deliver patient care and even lifesaving treatment. For this reason, they’re highly regulated by the Food and Drug Administration (FDA). As a result, all medical devices must pass strict regulatory policies before entering the market.

Contract manufacturers are responsible for managing this complex task. That includes having the procedures, equipment, and policies in place to meet these standards. They must also keep up with the changing requirements to ensure all devices meet FDA guidelines.

Ensure Quality Compliance

If a product fails to meet quality standards, lives could depend on it. That’s why it’s an important role of the contract manufacturer to prevent quality issues.

Medical device contract manufacturers are responsible for inspecting and assessing all products before they reach the market. Staff performs inspections throughout the production process using sophisticated measuring equipment to ensure corrections can be made promptly. In addition to the quality control of individual products, it’s the contract manufacturer’s responsibility to identify potential areas for improvement in the production process.

It’s also the job of the contract manufacturer to follow ISO 13485 guidelines. This confirms the effectiveness of the quality management system while also ensuring the safety and efficacy of the parts produced. ISO 13485 compliance includes process validation protocols, such as IQ, OQ, and PQs.

Improve Medical Device Design

The role of a medical device contract manufacturer goes beyond production. Many manufacturers will also have on-site engineering teams to help OEMs refine each device's design and manufacturing process.

From design consultations to injection mold development, contract manufacturers guide OEMs every step of the way to ensure that they get the best possible plastic components or devices. This doesn’t just help companies produce products of excellent, reliable quality — it can also help minimize downtime, save money, and meet production targets.

Manage the Supply Chain

A contract manufacturer is responsible for buying all parts and raw materials, warehousing supplies, managing production schedules, and hiring to fill important positions like assembly workers, technicians, and engineers.

When it comes to supply chain management, medical device contract manufacturers are in a unique position to make the cost of production more affordable. They can negotiate for lower prices and shorter lead times, which can help OEMs get their products on the market quickly and at a reasonable price.

Handle Production from Start to Finish

From warehouse space to staff salaries, in-house production can quickly get expensive for OEMs. A contract manufacturer can take on the upfront burdens of production, whether it's a small-scale prototype or a wider rollout of millions of products. They can also manage the other services that go into putting a medical device on the market, like packaging, welding, decoration, and sterilization.

When all of this is taken care of by the contract manufacturer, OEMs are free to focus on their innovation. Instead, they can put resources toward what matters for their business — improving the lives of their customers.

The Right Medical Device Contract Manufacturer for You

If you’re looking for the right medical device contract manufacturer to work with, there’s a lot to consider. A great partner won’t just meet the necessary industry practices. They should go above and beyond to provide a top-notch production experience that enables you to bring high-quality products to market quickly and affordably.

At Crescent Industries, we strive to be the industry's most reliable plastic device contract manufacturing provider. With over 75 years of injection molding experience, we make quality a priority. Learn more about what we do or contact us for a quote today.

Resources:

https://www.medicaldevice-network.com/comment/medical-device-contract-manufacturing-demand/

Topics:

Related Articles

-

Mar 17, 2025

Labware & Diagnostic Injection Mold Building and Molding

Read MoreMedical device molding requires much higher levels of precision injection molding and tolerance...

-

Jan 10, 2025

Benefits of a Plastic Medical Device Manufacturer

Read MoreReusable and single-use plastic medical devices are held to high standards of sanitation, texture,...

-

Jun 07, 2024

The Key Benefits of ISO 7 Cleanroom Standards for Injection Molding

Read MoreThe International Organization for Standardization (ISO) sets strict standards for the safety and...