What are Parting Lines and Weld Lines in Plastic Injection Molding

(Updated May 2019)

Parting lines and weld lines are important subjects for product designers and mold designers. An awareness of both is a good first step.

Parting Lines

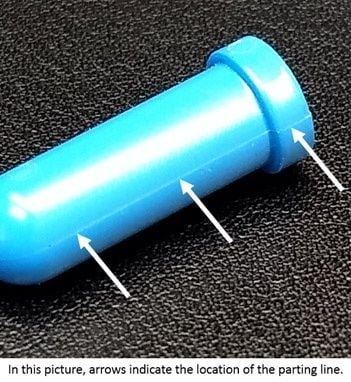

When referring to injection molded parts, the phrase “parting line” refers to a line on the part that is created where the two halves of the mold come together. What results is a faint, sometimes unnoticeable line on the part. This line usually doesn’t affect the overall shape or dimensions of the part, but can be visually noticeable to varying degrees, depending on mold finish, material type, material color, and processing parameters. There are several ways to make this line less noticeable on the molded part, but because injection molding relies on a mold that has two halves, it can never be avoided completely.

The parting line will usually be determined by the geometry of the part. The mold designer’s goal is to choose a location for the parting line that will create the most robust tooling design, while at the same time making it less noticeable. However, he/she is often constrained by the design of the part. The parting line usually needs to follow the outside contour of the part, and it needs to allow all the features  of the part to clear the tooling in the direction that the mold opens. Injection molded parts also need to be drafted for release from the mold, and the locations and directions of this draft will influence the parting line location. For these reasons, careful consideration of the part design is needed so that the location of the parting line is in the best place possible, as determined by the application of the part.

of the part to clear the tooling in the direction that the mold opens. Injection molded parts also need to be drafted for release from the mold, and the locations and directions of this draft will influence the parting line location. For these reasons, careful consideration of the part design is needed so that the location of the parting line is in the best place possible, as determined by the application of the part.

Parting line placement will also affect the cost of the mold. The simplest and strongest parting line is one that exists on a single, flat plane. However, because of the complexities of many injection molded parts, this type of parting line is not always possible. Parts that have an elaborate contour often have more cost associated with the mold, since the parting line usually needs to follow along this contour. The part designer can oftentimes reduce mold costs by controlling these issues in the part design phase. From an injection molding standpoint, a well-designed part has a clearly defined parting line, which has been designed to be as simple as possible.

Other than part design, certain techniques can be used in the design of the mold to ensure a better and less noticeable parting line. Any misalignment between the two halves of the mold will create a mismatch at the parting line. The result can be more than just a visible line, but an actual step in the part, which will affect the part dimensions and make the parting line more noticeable. Accurate machining practices and additional alignment features in the mold will mitigate this problem.

Weld Lines

A weld line refers to a line, notch, or color change that is created on the molded part caused by the convergence of two separate flows of molten plastic. This occurs wherever  there is a hole, notch, or any other feature on a part that divides the flow of plastic into 2 separate “flow fronts.” As these flow fronts come together on the other side of a given feature, the molten plastic rejoins or “welds” together and often forms a slight line on the part, similar to a parting line mark. At the spot where the two flows rejoin, there is inadequate interfusing of the plastic – perhaps because there is already partial cooling and then re-solidification of the plastic at this point, or perhaps on a molecular level the molecules are not oriented in the same direction of the flow path. In any case, the result is a weld line and in some cases a reduction in strength.

there is a hole, notch, or any other feature on a part that divides the flow of plastic into 2 separate “flow fronts.” As these flow fronts come together on the other side of a given feature, the molten plastic rejoins or “welds” together and often forms a slight line on the part, similar to a parting line mark. At the spot where the two flows rejoin, there is inadequate interfusing of the plastic – perhaps because there is already partial cooling and then re-solidification of the plastic at this point, or perhaps on a molecular level the molecules are not oriented in the same direction of the flow path. In any case, the result is a weld line and in some cases a reduction in strength.

Just like a parting line mark, weld lines will be more or less visible depending on the condition of the mold and the process parameters during molding. Most of the time, these weld lines do not weaken the part unless the part is processed incorrectly.

In most part designs, the creation of weld lines is unavoidable, especially in certain designs such as those with holes. Weld lines are not a result of deficiencies in the raw material, mold, or process, but they can be minimized with good design, material selections, and processing conditions.

Below are some options that may resolve or move weld lines to a more desirable location for improved aesthetic or strength reasons; however, OEMs should work with their manufacturing partner before implementing these steps to ensure solving a weld line issue does not create a different problem.

- Increase the temperature of the mold or plastic material in order for the two flow fronts to interfuse better.

- The gate location influences where the weld line is on the part. Change the gate positions before the mold is fabricated to inject the material at more ideal locations and have weld lines in a more preferable location.

- Changing the product wall thicknesses will result in a different fill time, and may cause the flow fronts to meet at a different spot and move the weld line location.

- Adjust the design to be a single source flow to avoid the issue caused by two or more flow fronts.

- Reduce runner system dimensions to increase the molten plastic temperature at the front of each flow.

- Increase the injection speed to fill the mold more quickly and ensure the material does not prematurely cool down; in addition, when the speed is adjusted the flow fronts may meet at a different spot and move the weld line location.

- Change the raw material to a plastic with a lower viscosity or a lower melting point to improve flow properties.

- To avoid weld lines entirely, consider machining features, such as holes, into the part after the injection molding is completed.

In many cases, predicting the weld line and parting line locations is achieved using computer simulations. Engineers at Crescent Industries can help perform these simulations and are ready to help with advice and suggestions for your next injection molded plastic component or device.

Related Articles

-

May 20, 2025

Designing for Injection Molding Success: What Every Engineer Should Know

Read MoreDesigning plastic parts for injection molding is both a science and an art. From material selection...

-

Mar 19, 2025

Top 6 Advantages of Injection Molding for Your Project

Read MoreInjection molding — the process of injecting molten resin into a mold — is one of the most...

-

Feb 19, 2025

Injection Molding vs CNC Machining: Which Method to Choose?

Read MoreEvery year, humans produce and use countless plastic products in various shapes, sizes, and...