Understand the Causes of Shrink & Warp in Plastic Injection Molding

(Updated May 2019)

To understand the causes of shrink and warp in custom plastic injection molding, it is essential to comprehend what shrinkage is. Shrinkage is a reduction in the size of the molded part as it cools. All injection molded parts shrink, but they do this by different degrees.

The amount of shrinkage needs to be accurately predicted. This can best be determined by part size and resin selection.

The reality is that different plastics shrink more than others. Some plastics shrink differently in one direction than in the other.

For example:

- Polymers filled with long glass fibers will shrink more in the cross direction than in the longitudinal direction. The material supplier will tell you that you have to use a different shrink in the X-axis than in the Y. If close tolerances matter - do not use asymmetrical shrinkage resins.

- Crystalline and semi-crystalline materials are particularly prone to thermal shrinkage. Amorphous materials tend to shrink less.

- Resins that are filled vs unfilled – fillers such as fiber, for example, often do not expand or contract as temperature changes, thus, filled resins generally shrink less than unfilled resins (resins can be filled with various materials, such as glass fiber, wood and mica to change the part’s properties).

The shrink of the resin must be taken into account when designing the mold. The cavity that forms the part is designed slightly over-sized to allow for shrinkage.

Understanding the Causes of Shrink and Warp in Custom Plastic Injection Molding

Your injection molder can fine-tune the shrinkage of the parts by adjusting the density of the material, i.e.; how they have packed it out and how long they hold it to cool in the tool.

Shrinkage can be impacted by the following factors:

- The relationship of shrinkage to several processing parameters and part thickness, which is schematically plotted

- Low injection pressure, short pack-hold time or cooling time, high melt temperature, high mold temperature, low holding pressure

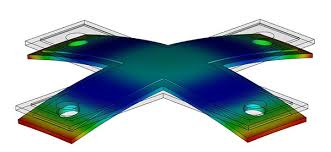

Achieving low and uniform shrinkage is a complicated task due to the presence and interaction of many factors such as molecular and fiber orientations, temperature variations within the molded part, and variable packing – such as over packing at the gates and under packing at remote locations or different pressure levels as the material solidifies across the part’s thickest area.

During the cooling step in injection molding, if a component cools and shrinks uniformly in all directions, the part becomes smaller but retains the desired shape. However, if the part does not shrink uniformly due to variation in shrinkage both globally and through the cross section of a part, internal stresses or residual stresses are created. These stresses act on a part with effects similar to externally applied stresses. If the residual stresses induced during molding are high enough to overcome the structural integrity of the part, the part will warp upon ejection.

Warping, or warpage, is a distortion in the intended shape of the molded part that occurs during cooling. Warping can make the parts twist, fold, bend, and bow. Mold design should consider the potential for part warping which can be caused by non-uniform mold cooling.

Variations in part thickness – the differences in shrink rates between thick and thin areas can also cause the part to warp, as can improperly gated parts.

Reducing and Controlling Shrinkage and Warping

There are a few options to reduce or control shrinkage and warping.

- Avoid non-uniform wall thickness to facilitate a more uniform flow and cooling across the part.

- Balance the filling pattern, and use a proper packing pressure level. This allows sufficient packing time and removes the pressure after the gate freezes.

- Allow adequate cooling time and ensure it is slow enough to avoid the creation of residual stresses in the part.

- Check the gate design and locations to ensure they provide a uniform flow pattern through the part to avoid shrinkage variations.

- The cooling system should be designed to apply uniform cooling across both thickness and throughout the part; consider conformal cooling if traditional cooling methods are not adequate.

- Select raw materials that are less likely to shrink and deform such as filled resins or amorphous polymers.

During the design phase, work with your molding partner to perform a DFM analysis to model the part, identifying potential shrinkage or warpage concerns and adjusting the design as necessary to address the issues.

For additional information, please click below to get our white paper “How to Overcome Common Design Concerns for Injection Molded Components”. This white paper addresses some of the key concerns in the design step that are a 'must' to consider.

Source information: Shrinkage: Chapter 8, by Professor Joseph Greene at California State University

Topics:

Related Articles

-

Mar 19, 2025

Top 6 Advantages of Injection Molding for Your Project

Read MoreInjection molding — the process of injecting molten resin into a mold — is one of the most...

-

Feb 19, 2025

Injection Molding vs CNC Machining: Which Method to Choose?

Read MoreEvery year, humans produce and use countless plastic products in various shapes, sizes, and...

-

Oct 03, 2024

Injection Molding Uses: Exploring Applications Across Industries

Read MoreInjection molding is one of the most versatile manufacturing processes, with a wide range of...