The Future of 3D Printing: A Look at Manufacturing and Medical Applications

3D printing has made a major impact on the medical and manufacturing industries, and its capabilities are growing. As the technology improves and advances, the future of 3D printing holds great promise to continue evolving, yielding nearly limitless opportunities.

3D printing's future applications range across the full gamut of the production process, helping manufacturers achieve innovations, improve their products, and realize unprecedented efficiencies. The future of additive manufacturing is intertwined with that of manufacturing as a whole. In this article, we will explore how 3D printing will support and drive these processes.

3D Printing for Medical and Manufacturing

3D printing is currently used in manufacturing for the medical field in numerous ways:

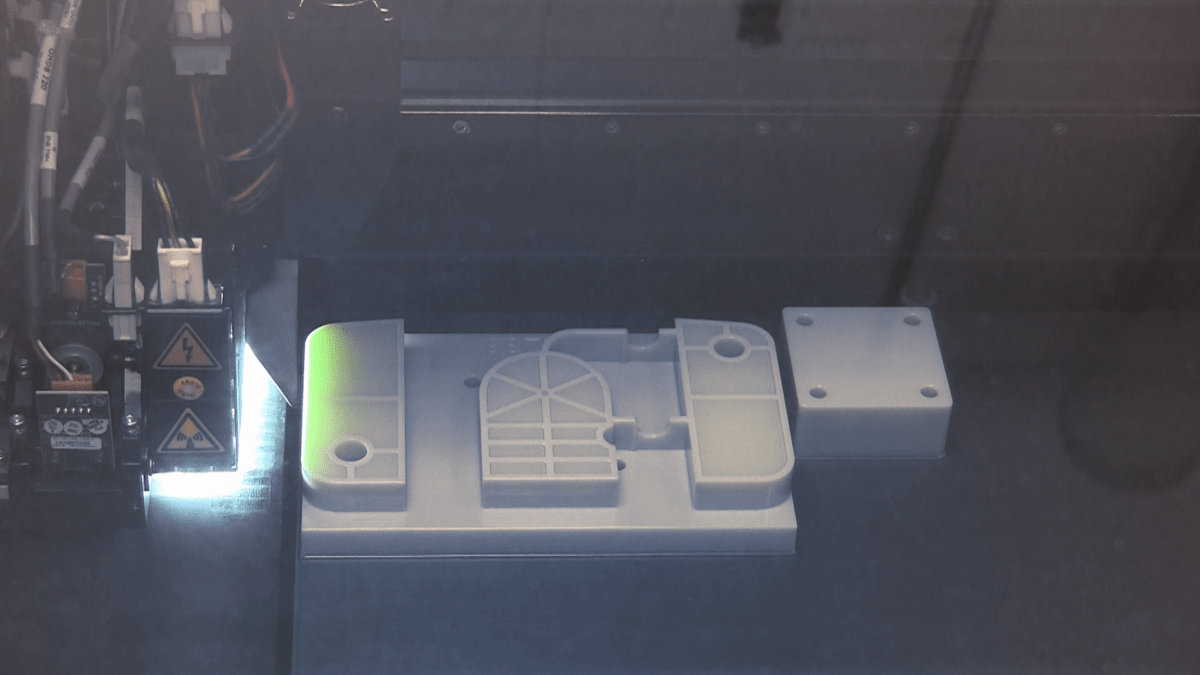

- Rapid prototyping for injection molded components: As a prototyping method for injection molding projects, 3D printing affords significant benefits — including increased prototyping speed, reduced costs, and more flexibility in design. By cutting turnaround times for prototypes and reducing the cost of getting a prototype into designers’ hands for further analysis and iteration, 3D printing allows projects to proceed more quickly, and to achieve innovation and quality that may not have otherwise been feasible.

- Design for manufacturability: Manufacturability is a key consideration in injection molding since low manufacturability means that a part will be difficult or even impossible to injection mold properly and efficiently. 3D printing assists in design for manufacturability by creating fully functional, production-grade prototypes. Designers and other stakeholders are enabled to determine whether a part or product can be effectively created with the specs and features that injection molding requires.

3D Printing and the Future of Manufacturing

The future of 3D printing in medicine and manufacturing is bright for all parties involved. 3D printing continues to advance — with more efficient and accessible machines, higher-quality, more versatile materials, and innovations developed by today’s workers and researchers. Thus, it will play a major role across manufacturing and provide benefits for other production processes, such as injection molding. Some examples of how to include:

- Increasing speed and cost benefits for prototyping — allowing for even more iteration, risk-taking, and innovation to push the envelope of product development.

- Endless customization and personalization potential, with 3D printed add-ons and components able to be quickly and easily manufactured to modify stock, “out of the box” molded medical equipment and devices. In areas such as prostheses and implants, this combination will yield incredible quality, speed, and efficacy benefits.

- As 3D printing evolves, product designers and developers across industries will be able to use the technology to quickly model existing structures — such as, in the medical field, patient-specific body models. This practice will allow for unparalleled research and development of medical devices and treatments.

At Crescent Industries, we make extensive use of 3D printing to support our injection molding services. Our team could not be more excited about the future of 3D printing to allow us to continue providing you with top-quality products. We look forward to discussing our services and processes with you, and how we can best use them to solve your problems in medical manufacturing and beyond. Contact us today.

https://www.crescentind.com/3d-printing-prototypes

https://crescentind.com/medical-and-pharma-injection-molding/

https://crescentind.com/custom-injection-molding/

http://www.plasticsnews.com/article/20160421/BLOG01/160429949/in-the-future-will-everyone-be-a-plastics-processor

https://3dprint.com/113680/3d-printing-tech-of-2015/

https://www.huffpost.com/entry/how-3d-printing-will-driv_b_11303842

http://www.healthtechzone.com/topics/healthcare/articles/2019/08/07/442906-why-3d-printing-perfect-medical-applications.htm#:~:text=Common%20medical%203D%20printing%20applications,potentials%20of%20the%20medical%20field.

https://www.docwirenews.com/future-of-medicine/infographics/how-3d-printing-has-changed-the-game-in-the-medical-field/#:~:text=3D%2Dprinted%20materials%2C%20in%20the,in%20developing%20practices%20and%20research.&text=The%203D%20printing%20industry%20has,more%20than%2035%25%20since%202014.

https://www.futuremedicine.com/doi/10.2217/3dp-2019-0010

Topics:

Related Articles

-

Jul 24, 2024

The Evolving Landscape of Custom Injection Molding

Read MoreA big part of establishing your foothold in any industry is adopting—or at the very least, staying...

-

Nov 21, 2023

3D Printing vs Injection Molding: Pros and Cons

Read MoreMany manufacturers compare 3D printing vs. injection molding to determine the best method for...

-

Nov 02, 2023

A Guide To The Overmolding Process

Read MoreAlong with its ability to create high-quality soft-touch grips, the over-molding process benefits...