How to Use Mold Filling Simulation to Ensure Part Manufacturability

Mold filling simulation is part of the design for the manufacturability process that cannot be skipped. The findings of a simulation allow part designers and engineers to make critical decisions about the design before the injection mold is manufactured, while changes are significantly less expensive.

For OEMs planning to manufacture a plastic part, it’s important to work with a contract manufacturer that has in-depth experience and training in mold filling simulation and has invested in state-of-the-art simulation software. Even when working with a qualified CM, it is helpful for OEMs to know what to expect from a mold filling simulation, including:

- What mold filling simulation is and how it works

- How the simulation informs decision-making in the design and manufacturing processes

- Types of mold filling simulation software available

The Mold Filling Simulation Process

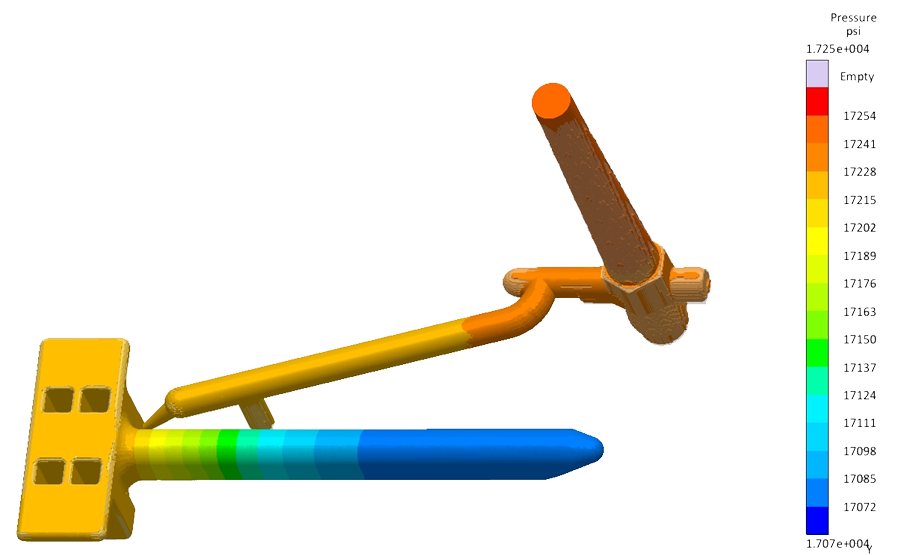

Mold filling simulation is a process that ensures the manufacturability of a part by virtually simulating the filling of the mold. Specialized software is used to simulate all of the mold filling processes, including the filling, packing, and cooling of a molded part.

Simulations can be run based on an imported part design or mold design, or a process simulation can be conducted. If a part exists from previous manufacturing, engineers can take the existing part, load it directly into the software, and simulate the entire injection molding cycle.

Engineers and part designers use the simulation output to identify an extensive range of items on the DFM checklist — such as sink marks, voids, high pressures, high temperatures, and warpages. These can then be resolved by revising the design before manufacturing.

Decisions Impacted By Mold Filling Simulation

Mold filling simulation helps prepare for part manufacturing because it allows part designers and engineers to make informed decisions regarding:

Part design, including:

- Wall thickness

- Coring

- Draft

- Texture

- Ribs

- Bosses and gussets

- Living hinges

- Threads

- Special features and undercuts

- Text

- Use of two parts instead of one

Mold design, including:

- Sprue/cold material trap design

- Mold classifications

- Runner design

- Gate designs

- Cooling/heating

- Venting

- Side actions and other undercut solutions

- Shut-offs

- Shrinkage

- Warpage

Common issues that designers and engineers find and correct during mold filling simulation include:

- Problems with gate location(s)

- Areas where filling is a problem

- Weld lines (areas where two flow fronts meet) that aren’t strong enough

- Excessive shrinkage and warpage

- Areas that will trap air during filling

- Areas that will create sink marks

Based on the mold filling simulation, engineers can also develop a process that the molding department can use when they set up the mold in the press for the first time.

Mold Filling Simulation Software and Features

There are a variety of mold filling simulation software packages, each with its attributes and specific applications. Typically these are provided via the purchase and renewal of a software license. An important qualification of injection molding contract manufacturers is that they continually invest in state-of-the-art mold filling simulation software and maintain training in the software so that they can provide DFM services for their customers.

Some of the most popular mold filling simulation software packages include:

- Sigmasoft: Sigma Engineering publishes a suite of software packages — Thermoplastic, Thermoset, Elastomer, and MIM/CIM — to match the requirements of particular end materials and processes. The software creates a 3D simulation of flow, heat flux, and warpage that allows for the reproduction of processing conditions over several production cycles.

- Moldflow: Published by Autodesk, this software anticipates the basic challenges of plastic injection molding, including whether the mold will fill completely, the occurrence of part warpage or visible defects, possible improvements to the part geometry, materials, wall thickness or gate location, and how decreasing cycle time or temperature could affect part quality.

- Simpoe-Mold: Published by Dassault Systemès, this software offers mold filling simulation via two products, one just for plastic part designers (ENG) and one for plastic part designers as well as mold designers and mold makers (TOOL).

- Solidworks Plastics: Also published by Dassault Systemès, this software adapts the company’s mold filling simulation software by providing a graphical user interface for users of CAD. Three options are available, one for part designers, another for mold designers or builders, and a third for CAE analysts and others.

- eDesign Basic, eDesign, Moldex Professional, and Moldex Advanced: Published by Moldex3D, these software packages employ a full 3D boundary-layer meshing approach that offers fast processing times. The four packages are tailored to different roles in the design and manufacturing process.

- Creo Mold Analysis: Published by PTC, this product is based on Moldex3D technology and works on top of PTC Creo. It is used to analyze the design model, providing injection molding process simulation for preliminary product design directly within Creo.

- REM3D: Published by Transvalor, this software enables users to simulate filling, determine packing time, and identify best gate positions. Advanced features include handling water- and gas-assisted injection molding, overmolding, fiber reinforced materials, polyurethane foams, thermoset materials, injection compression, and injection of highly viscous fluids.

After conducting a mold filling simulation, engineers and product designers can address any issues that the simulation identified with the design, mold, materials, etc. OEMs and CMs can then proceed to the next step of their project, with the confidence that potential manufacturing problems have been prevented.

Topics:

Related Articles

-

Aug 11, 2025

DFM Done Right: The Value of Experience in Injection Molding

Read MoreDesign for Manufacturability (DFM) in plastic injection molding is a strategy that ensures...

-

May 20, 2025

Designing for Injection Molding Success: What Every Engineer Should Know

Read MoreDesigning plastic parts for injection molding is both a science and an art. From material selection...

-

Jul 24, 2024

The Evolving Landscape of Custom Injection Molding

Read MoreA big part of establishing your foothold in any industry is adopting—or at the very least, staying...