How to Make Sure Your Plastic Part is Moldable

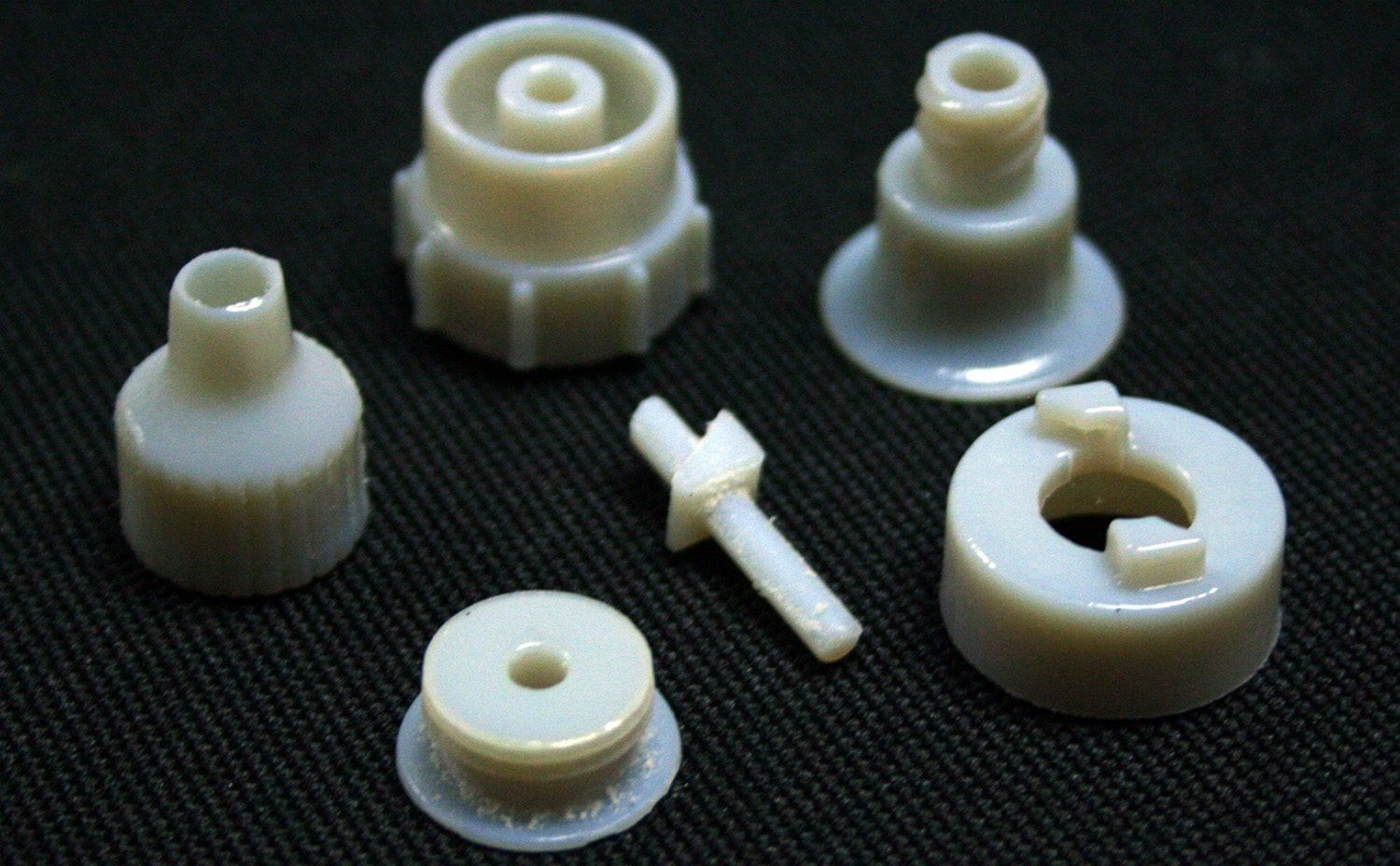

The creation of custom injection molded components has many aspects that need to be addressed. Some are subtle and some are obvious, but each is essential in ensuring a plastic part is moldable.

The creation of custom injection molded components has many aspects that need to be addressed. Some are subtle and some are obvious, but each is essential in ensuring a plastic part is moldable.

CONSISTENT WALL THICKNESS

It is important to use uniform wall thicknesses throughout the part, which minimizes sinks, warps, and stresses. The thinner the wall, the faster the part cools, which shortens cycle times and uses smaller amounts of plastic. This results in the lowest possible part costs.

When non-uniform thicknesses are used, the thick section cools slower than a thin section. When the thinner section solidifies first, the thicker section is still solidifying. As the thick section continues to cool, it shrinks. The material for the shrinkage comes only from the unsolidified area, which is connected to the thin section that has already solidified.

This shrinkage process builds stresses near the border of the thin section to the thick section. The thin section will not yield because it’s already solidified, so the thick section must yield. When the thick section yields, this causes warping.

Maintaining uniform wall thicknesses in the design phase reduces or eliminates warping since all sections cool at the same rate. If design limitations prevent uniform walls, then the thickness changes should be gradual. Coring can help in making the wall sections uniform, and eliminate the problems associated with non-uniform walls. Warping problems can be reduced by building supporting features such as ribs.

RIBS

Ribs help to strengthen part bending. Ribs can be used to avoid using thick sections, which saves on part weight and material cost. Make the rib thickness less (no more than 70 percent) than the nominal wall thickness to minimize sinking. Ribs should also have a draft.

Thick and deep ribs can cause sink marks, and filling problems and lead to ejection problems. It is better to use several smaller ribs rather than one large rib.

Where ribs intersect, the thickness will be greater than the thickness of each rib. Remove material by coring to reduce wall thickness to prevent excessive sinking on the opposite side.

BOSSES

Bosses are used when a screw or threaded insert is needed. Bosses located at the corners of a part can result in thick walls that cause sinks, but bosses can be isolated using certain techniques. Bosses should be cored to the bottom to maintain uniform wall thickness. An ample radius at the base of the boss provides strength and enough draft, so the part can be easily ejected.

RADIUS

Using a substantial radius at all corners reduces stresses. Sharp corners greatly increase the stress concentration, which may lead to the failure of plastic parts. Sharp corners can be inadvertently created when a boss is attached to a surface, or by building up a rib, so be sure these corners have generous radii as well.

DRAFT

It’s important to design plastic parts for easy ejection from the mold by providing a draft in the direction of the mold opening or closing. Without a draft, parts may not eject easily from the mold, which can damage the parts and the mold itself. Also, parts may bend, break, or warp due to stresses caused by cooling. The absence of a draft can cause costly and time-consuming delays.

SPECIAL FEATURES

Features of a plastic part generally need to be able to be released in the same direction. Any part features (holes, undercuts, shoulders, etc.) that cannot be released in the direction of the mold separation will require either redesign or special attention. Mold components called side actions can be used, which pull coring in a direction other than the direction of mold separation allowing flexibility to part designs but also increasing the price of the mold.

A through hole is preferred over a blind hole because core pins that produce a hole can be supported at both ends and are less likely to bend. Holes in the bottom of a part are better than holes in the side of the part, which require retractable core pins.

MATERIAL

Determining the proper raw materials for a plastic component’s specifications and requirements is an important design consideration. For function and performance, take into account that certain materials fill out thicknesses better than others do, and some have uniform shrinking compared to other materials. Other material considerations include flow, moisture, and chemical reactions during processing. Understanding the product needs and the end user requirements ensures the product is manufactured efficiently and intelligently, eliminating wasted material and time.

SIMULATION

Conducting a mold fill using a computer-aided 3D simulation allows the evaluation of how the mold will perform during the custom injection molding process before fabrication of the mold. Mold and part designers can then make decisions about the design before the mold is manufactured.

The next step is to create a mold design with the proper gate locations, air venting, cooling, and actions. A mold designer understands the different aspects of a part that are critical to custom injection molding. When working with injection molded parts make sure you work with the mold designers, be sure to take advantage of their abilities to get the best product at the lowest price from a custom injection molding manufacturer.

The engineers at Crescent Industries are ready to help with advice and suggestions for your next injection molded plastic component or device. We use our knowledge as injection molders and mold builders, to partner with Crescent Industries for your next injection molded project.

Topics:

Related Articles

-

Mar 19, 2025

Top 6 Advantages of Injection Molding for Your Project

Read MoreInjection molding — the process of injecting molten resin into a mold — is one of the most...

-

Feb 19, 2025

Injection Molding vs CNC Machining: Which Method to Choose?

Read MoreEvery year, humans produce and use countless plastic products in various shapes, sizes, and...

-

Oct 03, 2024

Injection Molding Uses: Exploring Applications Across Industries

Read MoreInjection molding is one of the most versatile manufacturing processes, with a wide range of...