How Injection Molding Makes Complex Plastic Parts

Plastic injection molding is an adaptable and affordable manufacturing process for making plastic components and devices in low, medium, and large volumes. The process produces parts for various medical, pharmaceutical, defense, and industrial markets. These sectors often have complex part designs, which benefit significantly from injection molding.

However, the success of any plastic injection molding project depends on your product vendor's capability. Some project features complicate the manufacturing process and need sophisticated tooling, skill, and environmental controls. Luckily an expert injection molding partner like Crescent Industries has extensive in-house experience and technologies to help meet complex custom specifications1. Here's a look into a few critical factors that can identify a good molding partner for intricate projects and some molding solutions for complex component/device designs.

Key Factors That Determine the Molder's Capabilities

The success of any plastic injection molding project depends on your product vendor's capability. The key factors that contribute to your partner's ability to produce complex injection molded parts include:

Injection Molding Tool

The type of injection molding tool your vendor uses is another key determinant. Advanced engineering support and design for manufacturing (DFM) analysts are a must when designs have complex features. The DFM analysis can eliminate any problems or concerns in the tool design before the steel is cut, saving time and money by avoiding costly changes after the injection mold is fabricated.

Robotics and Mechanization

Robots and mechanization improve the quality and speed of the injection molding process. They can help reduce possible human errors, labor costs, and worker safety risks. Using robots to take over repetitive tasks can allow human employees more time to ensure that all parts meet quality standards.

Scientific Molding

Scientific molding is an approach that promotes the producibility of complex components over a long period. Cutting-edge data collection and analysis methods are employed to document each step to create a controlled process. Only an expert molder with broad experience and analytical skills can use this method effectively.

Which Complex Plastic Features Do Injection Molders Encounter?

Snap-Fit Joints or Clips

A snap-fit joint is a common interlocking feature that allows two plastic components to connect easily2. It's a small protrusion in the form of a bump, hook, or bead on injection molded plastic parts. You can apply pressure to click the protrusion into an adjoining compatible pocket or slot. Some everyday plastic products that use snap fits include:

- Electronic device covers

- Battery compartment lids

- Snap-on lids

- Backpack buckle clips

The best way to create this complex design involves sliding shutoffs in the injection mold design. A sliding shutoff prevents molten plastic from flowing into the area designated for the snap-fit, leaving room for two pieces to connect.

By properly aligning the mold opening direction, the skilled journeyperson and machinists at Crescent Industries can create a relief hole at the clip base. Alternatively, the molder can use side actions to create a snap-fit joint.

The design solution has to be perpendicular to the pull direction and aligned with the mold's parting line. The side action must also be constantly accessible and in contact with the part during the molding process.

Besides sliding shutoffs, expert crafters can also hand-load inserts to create snap fits. The inserts are small pieces of precisely machined metal that personnel physically insert and dislodge after each molding cycle.

Living Hinges

A living hinge is a thin, flexible plastic section that attaches two halves of a molded part. The feature reduces the number of needed plastic components, lowering manufacturing costs. Examples of everyday living hinges include2:

- Butterfly hinges on shampoo bottles

- Straight hinges on electronic packaging

- Child-safe hinges on medicine bottles

Expert design ensures the living hinge opens and closes multiple times without losing strength from repetitive strain.

The type of material is a critical factor in the design of living hinges. The material needs to be flexible enough to withstand repeated opening and closing. Crescent Industries works with an extensive range of engineered and commodity-grade resins to meet different product needs.

Polypropylene and polyethylene are the ideal choices for this design part3. They have a high melt flow and thus can fill thick and thin wall sections. This characteristic preserves the materials' high tensile strength, lowering the chances of cracking at the hinge.

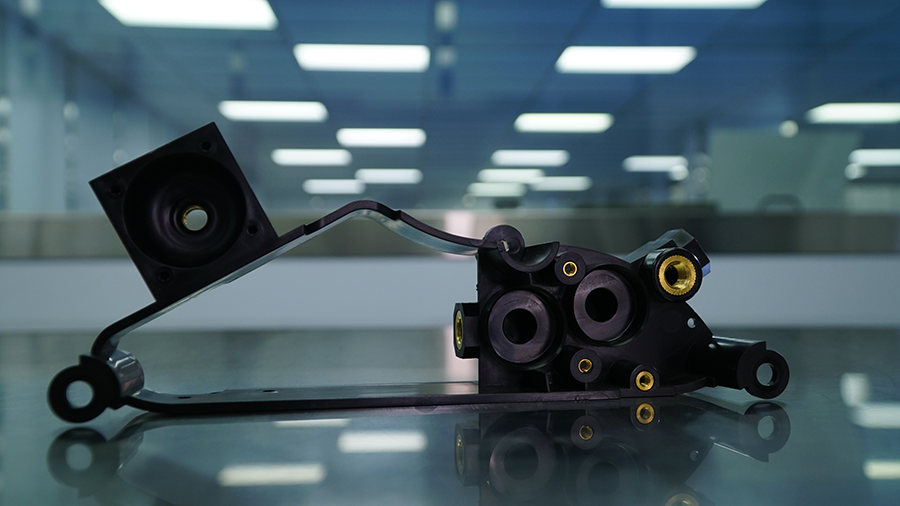

Bosses

Bosses are protruding cylindrical elements with holes designed to receive fastening hardware such as screws and threaded inserts. They are placed on the inner surface of plastic parts and help strengthen the final product.

These tall features often cause a problem during the ejection phase of injection molding. A hard ejection causes your plastic part to drag on the surface of the mold, resulting in drag marks. Draft angles of more than three degrees are needed to reduce these scratches.

Bosses can also develop sink marks on the molded part's even surface. Sink marks classically appear as depressions. The defect occurs when the inner molten plastic cools too slowly relative to the outer plastic. As the inner part cools, it shrinks, pulling the outer material inward. Thicker plastic components, often attached to bosses, develop these sink marks. Faster cooling needs a mold design with thinner wall parts to avoid these imperfections.

Choose Crescent Industries

Injection molding is a versatile manufacturing process that enables the rapid production of prototypes and finished products. However, accurate production of complex plastic parts requires an intricate tooling strategy and facilities. With Crescent Industries, you can enjoy a highly skilled technical team, precise molding presses, optimized tooling, and excellent inspection capabilities. Contact us for inquiries on complex plastic injection molding parts, and how we can help.

Sources:

Related Articles

-

Oct 08, 2025

Medical Device Cleanroom Manufacturing: Plastic Injection Molding

Read MoreWhy Cleanroom Manufacturing Matters for Medical Devices

Medical devices are subject to strict...

-

Mar 19, 2025

Top 6 Advantages of Injection Molding for Your Project

Read MoreInjection molding — the process of injecting molten resin into a mold — is one of the most...

-

Mar 17, 2025

Labware & Diagnostic Injection Mold Building and Molding

Read MoreMedical device molding requires much higher levels of precision injection molding and tolerance...