10 Factors That Impact the Injection Mold Cost

Learning these factors will help understand the tooling needed for your part design.

The most expensive asset to any OEM using injection molded products is their injection molding tool, so what factors are driving the cost? Tools can range from $15K if you’re using a MUD Frame (multi-unit die) on a simple part to well over $500K+ when you get into large tonnage and complex geometry.

There are several micro factors that play a part in the overall tooling cost. We will focus on the ones that drive that cost up or if controlled can keep the cost down. Depending on how many tools you are building every year, this could result in a minimum savings of $10K within the initial build and even more savings within the first 1-2 years of production.

1. Manufacturing Location

The USA vs Offshore tooling competition is still going on, and with the current tariff climate with the main supplier being China. For over 20+ years OEMs have been building tools directly in China and continue to compete with the USA on price. However, finding a high-quality tool shop in China has been a difficult task.The location is by far the largest impact on tooling costs, with two main factors causing the pricing difference; Labor rate offshore and quality of the tools built. Regardless of the tool shop, it’s a rarity to have an offshore tool perform the same as a USA made tool. With reduced labor rates, experience, technology and mindset, the tool manufacturing typically “cuts corners” causing future production issues.

- Offshore: Typically, significant initial cost savings however; build quality, language barriers and delivery time due to shipping can cause major issues. Once the tooling arrives in the USA, the process to modify or repair the tooling is often costly and time-consuming as US toolmakers have to transfer from metric to standard, tool damage, tools are built with soft steel so they are hard to fix; for this reason, the total cost of ownership is often higher for offshore fabrication locations.

- USA: Pricing will be higher when compared to offshore (range from 20%-40% more), but you get what you pay for, and having the peace of mind for tooling samples from your production supplier along with higher quality is well worth the extra costs. Additionally, molds built in the USA typically require fewer repairs, driving down the total cost of ownership.

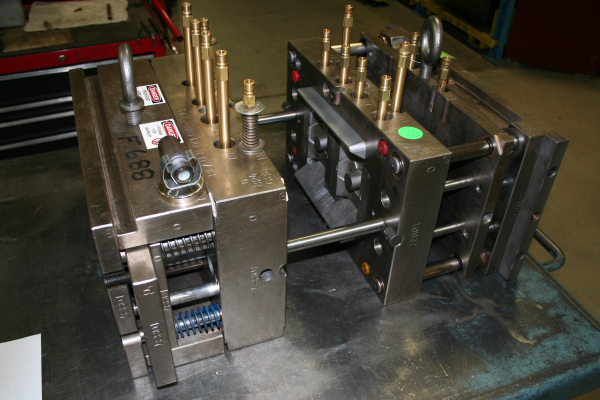

2. Mold Classifications

Options, options and more options. The injection mold SPI class as defined by the Plastics Industry Association (PIA, formerly SPI) sets standards on the physical tool construction and life expectancy. By selecting the appropriate “mold class” for your application, you can save a significant amount of costs by not over-engineering the tool.

To determine which mold class you should proceed with, beginning with the “life expectancy” and “tool material” will be a good starting point. If your project has a short life expectancy with a commodity grade material or an engineered grade that is not abrasive, you can start at Class 105 or “prototyping” mold class.

Mold Class 101: (Rated for One Million or More Cycles) Mold design required. Mold base should be a minimum hardness of 280 BHN. Molding surfaces (cavities and cores) must be hardened to a minimum of 48 Rc. All other details, such as slides, heel blocks, gibs, wedge blocks, etc., should also be of hardened tool steels. Ejection should be guided. Slides must have wear plates. Temperature control provisions to be in cavities, cores and slides wherever possible.

Over the life of the mold, corrosion in the cooling channels decreases cooling efficiency thus degrading part quality and increasing cycle time. It is recommended that plates or inserts containing cooling channels be of a corrosive resistant material or treated to prevent corrosion. Parting line locks are required on all molds.

- Mold Class 102: (Rated for no more than one million cycles) Mold design required. This mold is identical to the Type 101 with the following items not required: guided ejection, hardened slide wear plates, plated water channels, and, wear plated cavities. All other extras are optional. This tool is a medium to high production tool that is good for abrasive materials and/or close tolerance products.

- Mold Class 103: (Rated for Under 500,000 Cycles) Mold design recommended. Mold base should be a minimum hardness of 165 BHN. Cores and cavities must be 280 BHN or higher. All other extras are optional.

- Mold Class 104: (Rated for Under 100,000 Cycles) Mold design recommended. Mold base can be of mild steel or aluminum. Cores and cavities can be of aluminum, mild steel or any other agreed upon metal. All other extras are optional.

- Mold Class 105: (Rated for no more than 500 cycles) The mold base may be constructed from cast metal or epoxy or any other material offering sufficient strength to produce the minimum prototype pieces. This tool is only for prototype purposes only. All other extras are optional.

3. Mold Complexity and Aesthetics

Part design simplicity goes further than the performance on the OEMs product. An over-engineered and complex design can render a product not manufacturable and add unneeded complexity in the tool. And higher complexity molds lead to higher tooling costs.

Several mold design decisions impact tooling costs such as tight tolerances, engraving, or the addition of undercuts, actions, slide lifters, cams, unscrewing cores, hand loaded inserts, etc. These features drive up the cost of tooling. OEMs should look at design alternatives – for example, can the parting line or draft angle be adjusted for a less complex mold? Or can more production-friendly font settings be used to improve manufacturability? If any case, OEMs should ensure any complex features are “must-haves” and be ready to pay extra for them!

Thinking ahead to the production phase, any unneeded complexity will also increase beyond the initial tooling investment and into the production piece price. It is of the utmost importance for a full DFM analysis to be completed to reduce tooling and production costs on the project. It is also important to partner with a supplier that is able to provide design and production support, such as DFM, to confirm during the design phase that any challenging geometries or features are workable and will not result in issues during production.

4. Mold Cavitation

While production volume drives run and release quantities at your injection molding supplier, for every cavitation added the tooling cost will increase. This cost increase would then result in a reduction in piece part cost but depending on the annual volume of the project it might not be worth the extra upfront expenses. While sometimes this tooling cavitation increase is required for future production capacities, there are times when mistakes happen and there are too many cavities for the requirements.

5. Material Selection

The mold material selected will depend on the required production volumes, cycle times, product finishes, and materials used during plastic injection molding. All of these factors impact the mold’s lifespan. Different mold materials offer varying applications and lifespans. There are two main categories of mold materials: steel and aluminum.

- Steel: steel is often considered the ideal mold material, but it is also the costliest. Steel offers a higher useful lifespan compared to aluminum and is preferred for higher volume production. Tool steel is known for its hardness, resilience, thermal stability, and compatibility with a wide range of plastic molding materials including high-temperature plastics. Examples of common tool steels include P20, 420 SS, H13 and S7.

- Aluminum: aluminum is more cost-effective but often has a lower life-span, making it ideal for lower production runs and prototypes. Aluminum is lighter weight and provides excellent conductivity which allows mold heating/cooling steps to be minimized.

In addition to the mold material selected, the raw materials used to manufacture the plastic part may impact tooling cost as well. For example, if the resin you choose is corrosive, requires high operating temperatures, or contains abrasive materials such as glass or carbon fiber; the initial tooling cost as well as on-going maintenance expenses are more expensive. In addition, highly specialized or exotic raw materials that are utilized due to their unique and desirable properties will also increase an OEMs costs and are often more difficult to supply.

6. mud tool set vs dedicated mold

Stand-alone, dedicated injection molds are ubiquitous, but there are other options. Tooling inserts can be used with a standardized "master mold frame" to save cost and mold build time. These types of tooling inserts, "MUD" inserts, only require the manufacturing of the tooling that forms the parts, while the other mold features, those items needed for the actual function of the mold, are contained in the master frame. This option reduces the initial tooling cost since the manufacturer bears the bulk of the mold costs. MUD frame tooling options are often advantageous for low to medium-size production runs that cannot benefit from high-volume economics. Ultimately, the decision to build a stand-alone mold or MUD toolset will depend on the mold complexity needed and economics based on the required production volume.

7.Gates

A gate is an opening in the part cavity that allows the molten plastic to enter. The design and location of the gate have a big impact on tooling cost, cycle times, and cosmetics of the finished part. There are many gate designs available depending on the desired size, shape, and aesthetic of the product – below are a few of the most common:

- Sprue or direct: with this design the part is fed directly by the sprue. These are typically easy to design and manufacture since there is no runner or gate. The benefits of this design are that no material is wasted by molding a runner or gate, and you can fill a very large part with this design. The downside is it leaves a large scar at the point of contact that may need to be machined off, adding labor and leaving tool marks on the part.

- Edge: this gate is rectangular where it touches the part and reduces in width and height from the runner. With this gate type, the plastic enters where the two mold halves meet (parting line), filling the cavity from the side of the part and requiring that the gate be broken off after molding. The reduction in size from the runner helps it to break close to the part, leaving a small rectangular “vestige”, or visible gate remnant, on the part. This gate design is often inexpensive.

- Fan: this gate increases in width from the runner but reduces in thickness. This gate type is molded at the parting line and requires that it be broken off of the part after molding. Fan gates are often used when molding larger parts.

- Tunnel: this gate drops below the parting line so the cavity is filled from below, allowing for more flexibility in the gate location and more control over the location of the scar. The advantage of this gate type is that the part and gate/runner are automatically separated in the ejection stage. The drawbacks are that these gates are more expensive and cannot be used on bigger parts due to the small size of the gate where it enters the part.

- Valve: this type allows the independent opening of each gate to improve control over the flow of material through the gates, often resulting in better quality parts. These gates are more expensive than the more basic designs like edge or sprue.

- Hot Tip: with this type of gate, the plastic is kept molten all the way to the part cavity using heaters, eliminating the sprue, runner and gate, and reducing the amount of raw material used. A hot tip gate results in very little vestige and reduces the cycle time. This type of gate is typically expensive and is usually economic for high production runs.

Additionally, most molds are made of 2 plates but if a 2 plate mold does not provide for a suitable gate location, a 3 plate mold may be utilized. Three plate molds also allow a more precise, pinpoint style gating system on the top surface of the part. As one would expect, 3 plate molds are more costly given the higher tool complexity and machining required. These designs are often used when a part is too large for a 2 plate mold or more injection points are necessary.

8. Runner System

There are two categories of plastic injection molds: cold-runner and hot-runner. There are pros and cons of both systems and the “right” runner depends on the specific application. A cold runner, as suggested by its name, is comprised of unheated channels that distribute the molten plastic to the mold cavities. The molten material remaining in the cold runner system cools along with the molded part so every time the mold opens to eject the parts, the material in the runner is ejected as well and must be manually or automatically separated from the part. One of the disadvantages of cold runners is the waste produced each cycle from the cooled material in the runner and the time required to recycle and reprocess this material. Additionally, the time it takes to remove the runner from the part increases cycle times. On the flip side, cold runner designs are typically simpler and require less expensive tooling when compared with hot runners.

Hot runner designs consist of heated channels that distribute the molten plastic to the mold cavities. The material in the runners is heated within a manifold system that allows the plastic to remain at a consistent temperature, thus, the material in the runner is never cooled. The hot runner system is located on a separate plate, allowing the final part to be ejected without any runners attached – avoiding any waste generation and the time associated with removal of the runner from the final part. This type of runner design is typically more complex than cold runners, resulting in higher tooling costs. However, the faster cycle times and avoidance of waste generation are big advantages offered by hot runners.

9.Mold Finish

The surface of an injection molded part will take on the same surface finish of the mold. There are many options to achieve the desired degree of polish and texture. Given the significance of a part’s attractiveness, the finishing step in product design and production is becoming increasingly important. Finishes are typically designated using industry standards such as PIA or Mold-Tech. PIA finishes are often used for mold surface finishes and represent the extent of polish. Mold-Tech finishes refer to the desired texture. The value in using a standard is to ensure OEMs and manufacturers are aligned and speaking the same language!

It is also important to note that different plastics respond differently to mold surfaces. In some cases, a lack of texture from a very smooth mold surface may cause parts to stick to the mold; alternatively, a rough mold surface may cause ejection issues. This is why OEMs and manufacturers must work together during the DFM analysis to ensure the raw plastic material is suitable for a given mold finish – avoiding production issues in the future!

Tooling cost increases significantly with the finish – so it makes no sense to over polish or texturize a mold!

10. Cooling System

Different injection molding cooling strategies will impact the initial tooling manufacturing cost – the more sophisticated the cooling, the higher the tooling cost, and the longer the design and fabrication time. Traditional cooling methods are similar to a heat exchanger, often with long tubes, typically straight or U-shaped, running through the mold to facilitate part cooling. The advantage of this approach is lower tooling costs upfront, however, the part cooling may not be as uniform as desired.

An alternative approach is conformal cooling where the cooling channels closely follow the shape of the component being produced. Conformal cooling tubes follow the bends and turns of complex part designs and are not limited to the straight channels that are created by traditional drilling or milling. Although the initial tooling costs are higher, this cooling method results in better cooling efficiency and lower cycle times. Due to its more uniform cooling, this technique is also known for producing very high-quality parts that often result in fewer rejected products, which can be a real cost savings for high volume runs, and in many cases far outweighs the higher upfront tool cost.

Crescent Industries has been manufacturing injection molded tooling for over 75 years and has a rigorous process for addressing these 10 factors and many more – If you’re interested in discussing how we can help out on your project, then please “contact us today”! It’s time to partner with a company that is on the leading edge of manufacturing technology and continues to reinvest profits into the company’s capabilities.